Glossary of Terms

Plastic Spiral Binding Glossary

Book Block: The gathered signatures or gathered flat sheets of a publication before the cover is added.

Caliper: The measurement of the thickness of paper measured in thousandths of an inch or mils.

Collate or Gather: To gather flat sheets or printed signatures together in their correct order.

Collating Marks: A distinctive, numbered symbol printed on the folded edge of signatures to denote the correct gathering sequence.

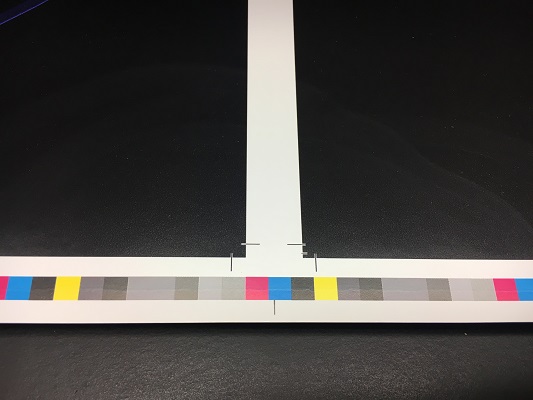

Crop Marks or Trim Marks: Small printed lines around the edges of a printed piece indicating where it is to be cut out of the sheet.

Pagination: The numbering of individual pages in a multi-page document.

Signature: A folded book section. A book is printed on a wide sheet or web of paper which is cut and folded into a book section. Usually as 4, 8, 16, or 32 page signatures.

Sig.Spine: The bound edge of a book.

Punch Depth: The distance from the edge of the sheet to the deepest part of the punch holes.

Pitch: This term denotes how many holes per inch. (It’s essentially a punching pattern.) For example, a 4:1 punch pattern will have four holes per inch.

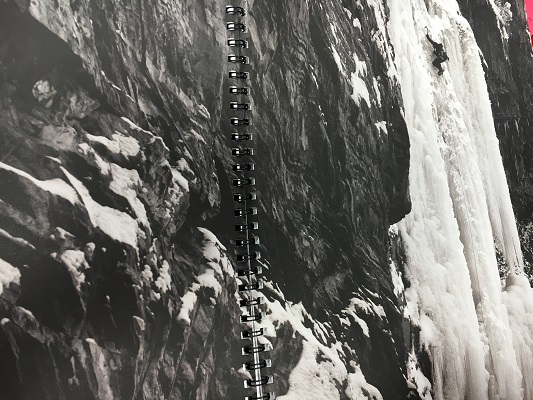

Wire-O Glossary

Book Block: The gathered signatures or gathered flat sheets of a publication before the cover is added.

Caliper: The measurement of the thickness of paper measured in thousandths of aninch or mils.

Collate or Gather: To gather flat sheets or printed signatures together in their correct order.

Collating Marks: A distinctive, numbered symbol printed on the folded edge of signatures to denote the correct gathering sequence.

Crop Marks or Trim Marks: Small printed lines around the edges of a printedpiece indicating where it is to be cut out of the sheet.

Pagination: The numbering of individual pages in a multi-page document.

Signature: A folded book section. A book is printed on a wide sheet or web of paper which is cut and folded into a book section. Usually as 4, 8, 16, or 32 page signatures.

Sig.Spine: The bound edge of a book.

Punch Depth: The distance from the edge of the sheet to the deepest part of thepunch holes.

Pitch: This term denotes how many holes per inch. (It’s essentially a punching pattern.) For example, a 4:1 punch pattern will have four holes per inch.

Perfect Binding Glossary

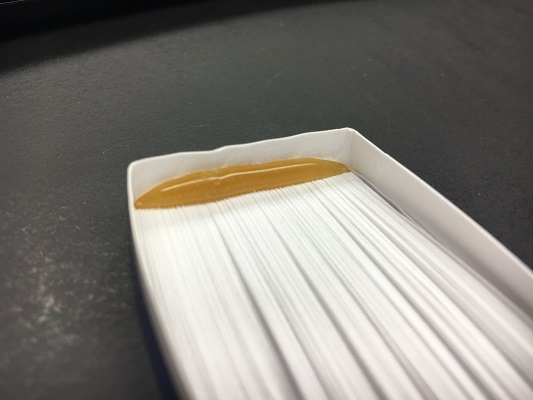

Perfect or Adhesive Binding: Type of binding in which single leaves are secured together solely with an adhesive applied to the spine text block . Animal glue, polyvinyl acetate adhesives are mostly used.

Bleed: The part of the image area that prints past the edges of the page and is removed during final trimming.

Book Block: The gathered signatures or gathered flat sheets of a publication before the cover is added.

Caliper: The measurement of the thickness of paper measured in thousandths of an inch or mils.

Collate or Gather: To gather flat sheets or printed signatures together in their correct order.

Collating Marks: A distinctive, numbered symbol printed on the folded edge of signatures to denote the correct gathering sequence.

Crop Marks or Trim Marks: Small printed lines around the edges of a printed piece indicating where it is to be cut out of the sheet.

Crossover: An image, rule or line art on one printed page that carries over to an adjacent page of a bound or folded work.

Face: The outer or outside margin of the book.

Foot: The bottom of the book.

Full Bleed: A page that has an image that prints all the way to the edges on all four sides.

Grain Direction: Direction in which the majority of the fibers in a piece of paper or board are aligned. Grain direction in all man-made materials used in book binding should run parallel to the spine of the volume.

Gutter: A blank space or margin between components on a printed piece or presssheet.

Head: Top edge of a sheet, or bound volume, opposite from the surface on which the volume rests when it is shelved upright.

Hinge Score: Flexible part of the cover on which the cover swings open.

Calendar Tinning Glossary

Calendar tin or slide: V-shaped colored metal strip.

Tin Wrap: The amount of paper that is folded up into the tin.

Eyelet: Single or double PVC eyelet that is attached to metal tin, used to hang a calendar, display or chart.

Plain Tin: Metal tin that is used to finish the bottom of a calendar, display or chart,allowing it to hang straight and flat.

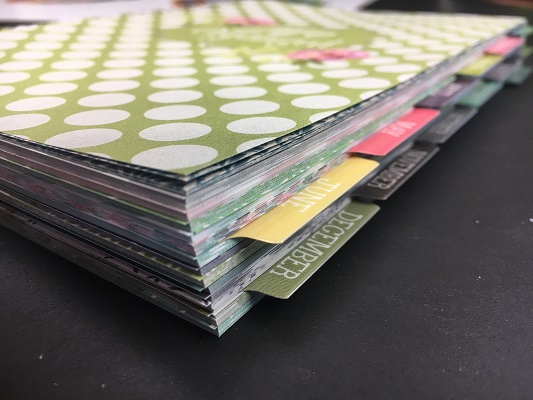

Index Tabs Glossary

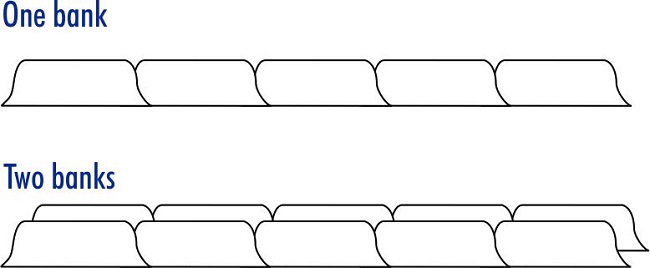

Bank: A complete row of same size tabs running the length of the face edge.

Body Copy: Any printing on the tab sheet other than on the tab extension.

Body / Overall Sizes: The body size of an index tab sheet is normally 8.5” x 11”. Itis the dimensions of the tab sheet without the tab. The overall size of an index tab sheet is normally 9” x 11”. It is the dimensions of the tab sheet with the tab.

Collating: The process of gathering individual tabs into complete sets.

Cut: The number of tabs in a bank. For example a 5th cut tab would have 5 tabs in a bank.

Tab Cutting: The process of cutting the tab extension out of the overall size tab sheet.

Drilling: The process of drilling holes in the tab sheets.

Edge Reinforcing: This is a 9/16” strip of Mylar applied to the back side of the binding edge of the sheet. It is used to strengthen the sheet. Applying edge reinforcing to the tab sheet will minimize the probability a tab will be torn off the rings. This is a wise investment if the tabs are going to be used frequently.

Extension: The length the tab extends out from the body of the sheet. The standard tab extension is 1/2”. This means a standard tab sheet with a body size of 8.5” x 11”and a 1/2” extension will always have an overall size of 9” x 11”.

Indent: Measures the distance from the top of the sheet where the top tabs starts or conversely, the measure from where the bottom tab ends to the bottom of the sheet.

Mylar: A plastic film used to strengthen and provide a variety of colors to the tab extension. It is applied using high temperature and pressure.

Per Set Pricing: The price of one set of index tabs. For example, Suppose you have 5 tabs in a set. A $1.00 per set price represents the price of all five tabs with the set. In this example the price per tab would be $0.20.

Tab Cut Only: A tab that has no mylar laminated to the tab extension.

Position: The location of the tab within a bank of tabs. For example, the first tab in a 5th cut bank of tabs would be in the 1st position. The second tab would be in the 2nd position, etc.

Set of Tabs: All the tabs contained in a single unit of your order. For example: if you have 5 tabs total, then the 5 tabs whether collated or uncollated make up a set.

Laminating Glossary

Border (Encapsulation) or Sealed edge: 1/16” to 3/4” overlap of laminate around entire sheet.

Rounded Corners: 1/8”, 1/4” and 3/8” rounded corners recommended on 5 mil and 10 mil. Rounded corners not recommended on 1.7mil or 3mil with border.

Clean grip and guide: the grip and guide edges of a press sheet have no overlapping film, the sheet can them be cut down, die cut, folded, scored, etc.

Flush: the sheet is laminated and trimmed to the edge to remove any excess laminate from all four edges of the sheet.

GS: Glueable/Stampable film enables surfaces to accept foil stamping and promotes gluing operations.

AGS: Animal Glueable/Stampable film enables surfaces to accept animal-based glues as well as foil stamping.

Hi-Tac and Superstick Film: Ideal for finishing toner-based and silicone fuser oil digital prints, it is a polyester-based film, an excellent choice for encapsulation.

Image Area: 1-sided laminating is an overlapping sheet fed process that requires a minimum of 1/2” around all 4 sides of your sheet. For example, the image area for a13” x 20” press sheet should be no larger than 12” x 19”.

Layflat or Nylon: Designed specifically to negate the effect of curl caused from moisture absorbed by paper. This film is scuff resistant, durable and adds high gloss to perfect bound books, dust jackets or any other areas where product flatness is critical. Layflat films are available in gloss and delustered finishes for 1-sided laminating.

Matte or Delustered: Non-reflective finish.

Polyester: films provide superior adhesion to full printed surfaces. Its high durability and abrasion-resistant qualities are well suited for almost all applications.

Polypropylene: films have an especially glossy finish with excellent folding characteristics. It is a beautiful and cost-effective alternative to polyester films.

Satin: Low gloss finish, developed to maintain color and consistency while creating a lower gloss sheen.

Scuff Resistant Matte: A polypropylene film that offers durable scuff resistant properties for superior protection for book covers and other applications during production and shipping, it accepts UV spot varnishes and is available for 1-sided laminating.